Hard Coat Anodizing Services (Type 3 Anodizing)

Clear and Colored Coatings offers Hard Coat Anodizing / Type III Anodizing. The hard coat process in separated into Class 1 (undyed) and Class 2 (Black dyed) aluminum anodizing. We’ve anodized parts for the manufacturing and industrial community for over 20 years with quality results delivered on each job.

For those who aren’t familiar with hard coat anodizing, we’ve broken down some key points regarding the process and its benefits.

What is Hard Coat Anodizing?

Hard Coat Anodizing makes aluminum more durable, dielectric, wear and corrosion resistant. The process involves forming an anodic coating of aluminum oxide on aluminum (and other non-ferrous metals) is known as electrolysis. This process occurs in a sulfuric acid bath utilizing low bath temperatures.

The base aluminum synchronizes with the anodic coating during this process. This helps form a strong bond with a thicker surface.

Benefits of Hard Coat Anodizing

- Enhanced Abrasion Resistance - Hard coat anodized aluminum has enhanced abrasion resistance. Its surface hardness is consistent, ranging from 400 to 600 HV across the entire aluminum part. With this type of hardness rating its often used for technical applications and far more wear resistant than conventional anodized aluminum. The final result offers a finish that’s harder than tooled steel.

- Increased Corrosion Resistance – Due to the thickness of the anodic / oxide film, hard coated aluminum is capable of resisting oxidation.

- Heat Resistance – Hard anodized aluminum is heat resistant. It can handle short periods at temperatures up to 2000°C. This is because of the coating's inert nature.

- Electrical Insulation – Hardcoat anodized aluminum parts have superior electrical insulation due to breakdown voltages. A typical anodic film created by the hard coat process ranges from 1011 to 1015 ohms.

- Readily Sterilized – Hard Coating process is readily sterilized and non-contaminate. This makes hard coat aluminum ideal for surgical equipment and medical instruments.

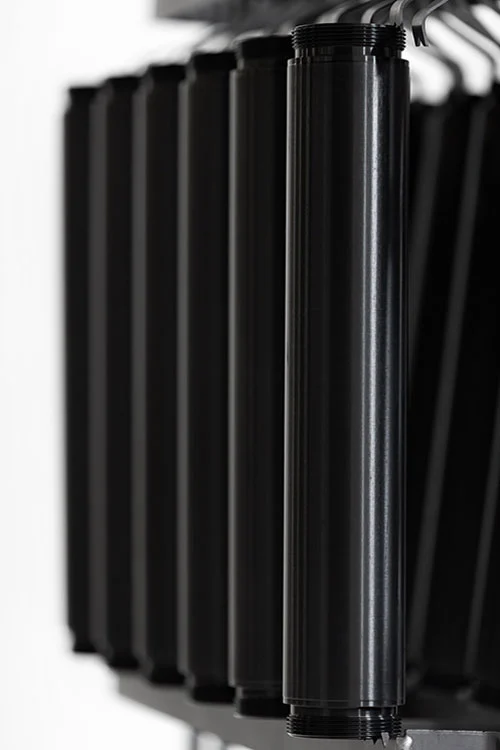

- Improved Aesthetic – The hard coat anodizing process changes the metal's color. This gives it a bronze-gray or dark gray/black complexion, depending on the aluminum's properties. We at Clear and Colored Coatings can dye the hard coated aluminum black which is considered Class 2 hard coating. Many manufacturers find the end result of the hard coating process to be aesthetically pleasing for their parts application.

Hard Coat Anodizing Applications

- Automotive

- Aviation

- Military (MIL A-8625 Type III)

- Surgical Instruments

- Compressors

- Cooking Ware

- Hydraulics

- Pistons

- Housing and Building Materials

What Is the Coating Thickness for Hard Coated Aluminum?

The coating thickness will vary depending on the aluminum material used during the anodizing process. Typically, the natural oxide layers on an aluminum surface are 2 to 3 nanometers thick. Once the aluminum has undergone the hard coating process, the coating thickness can increase to as much as 120 microns.

What Is the Appearance of Hard Coated Aluminum?

Class 1 Hard coat anodize will change the color of the aluminum to a bronze-gray or dark gray complexion. The color will depend on the particular alloy and the anodic thickness. Many of the 6xxx series aluminum have a dark gray-black color.

The 7xxx and 2xxx series aluminum have a bronze-gray color.

Class 2 coatings offer greater control of the color output. Clear and Colored Coatings provides black as an option for Class 2 hard coating. The black gives the hard coated aluminum an aesthetically pleasing, clean and uniform appearance.

Hard Coat Quality Depends on the Process

Anodizing is an essential metal finishing process and the final results will depend on those who are doing the process. Anodizing is a conversion coating. This means that part of the original aluminum is changed into aluminum oxide.

When dimensions matter, you need professionals who can held this process accurately. Clear and Colored Coatings can handle all of your needs when it comes to hard coat anodizing.

With over 40 years of industry expertise, we have the experience to get you from quote to final product in industry-leading turnaround time.

Want to see how Clear and Colored Coatings can help you?